While making our way, on foot, towards the massive Panthéon, we passed the relatively small but attractive, Gothic-style Église Saint Étienne du Mont Church, built between 1492 and 1655. It was described by French novelist Charles-Marie-Georges Huysmans (in the Connecting, 1895) as one of the most beautiful churches in Paris. It contains Paris’ unique and only surviving rood screen (built in 1535), dramatically crossing the nave like a bridge, separating it from the chancel, with spiral staircases on either side. During the Late Renaissance Period, the others were removed because they prevented the faithful in the nave from seeing the priest celebrate Mass.

It also houses the shrine containing the relics of St. Geneviève, the patron saint of Paris, until 1793 when revolutionaries burned the body, melted the relics at the Place de Grève (in front of the city hall) and threw them in the sewer. Only the tomb, lying in a chapel in the nave’s southeastern corner, survived. Near her tomb is a highly decorated reliquary containing a finger bone, all that is left of her earthly remains.

The church also housed the remains of important French figures such as Pierre Perrault (Receiver General of Finances for Paris and scientist), Eustache Le Sueur (painter), Blaise de Vigenere (diplomat, cryptographer, translator and alchemist), Blaise Pascal, (mathematician and physicist), Jean Racine (dramatist) and Isaac de Sacy Lemaistre (theologian and humanist). The last two were transferred in 1711 from Port-Royal in Saint-Etienne. The political theorist and scientist Jean-Paul Marat is buried in the church’s cemetery.

The church had its beginnings in the 6th century in the abbey of Sainte-Genevieve, where the eponymous saint had been buried. Devoted to the Virgin Mary and, later, to St. John the Apostle, the place was too small to accommodate all the faithful. In 1222, Pope Honorius III authorized the establishment of an autonomous church, this time devoted to St Etienne, then the patron saint of the old cathedral of Paris.

Soon, the new building, overwhelmed by an increasingly dense population, was enlarged in 1328. However, from the 15th century, a complete reconstruction soon became necessary and, in 1492, the monks Génovéfains donated a portion of their land for the construction of a new church. In 1494, under the direction of architect Stephen Viguier, the apse and the bell tower were sketched and, in 1491, the bell tower was built (the first two bells were cast in 1500). The flamboyant Gothic choir was completed in 1537 and, the following year, the frame was raised. The loft was built around 1530-1535, the chancel in 1537 and, in 1541, Guy, Bishop of Megara blessed the altars of the chapels of the apse. In 1545, the gallery was built and in 1580, the vaults of the nave and transept were built.

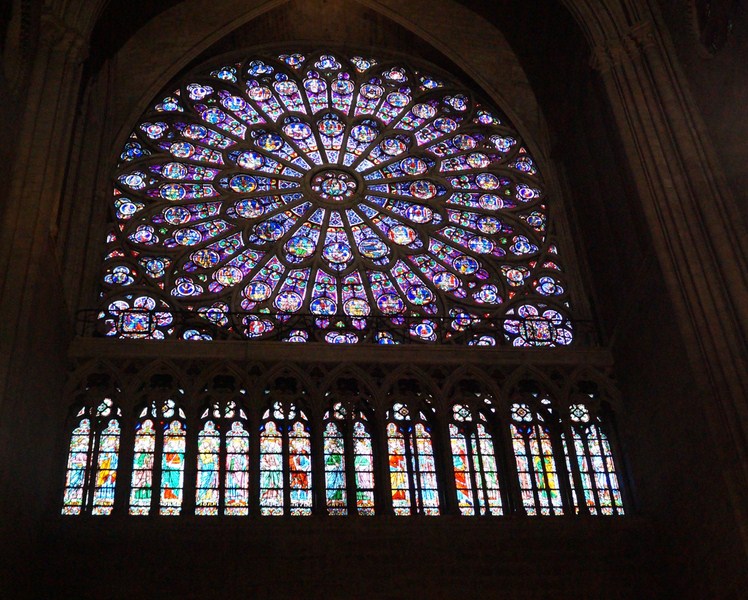

That same year, the parish awarded contracts for the windows and statues from Parisian artisans. The nave, from the Renaissance period, was not hunched before 1584. In 1610, the first stone of the facade was laid by Marguerite de Valois (who personally donated 3000 pounds) and, on February 25, 1626, the church was dedicated by Jean- François de Gondi, the first archbishop of Paris and Cardinal de Retz‘s uncle. In 1636, the organ (the work of Pierre Pescheur) was installed and, in 1651, a new pulpit was installed.

During the 17th and 18th century, the church enjoyed great prestige as the scene of great processions wherein the shrine of Sainte-Genevieve went to Notre Dame Cathedral and, subsequently, was returned to this church. During the French Revolution, the church was closed and then turned into a “Temple of Filial Piety.” in 1801, benefiting from the Concordat, Catholic worship was restored. During the Second Empire, the church was restored by Victor Baltard (who also built the chapel of catechisms), the front was raised and the statues, destroyed by the revolutionaries, were returned.

On January 3, 1857, Bishop Marie-Dominique-Auguste Sibour (who was to inaugurate the novena of St. Genevieve) was assassinated here, with cries of “Down with the goddesses!,” by the priest Jean-Louis Verger who opposed to the dogma of the Immaculate Conception. A plaque, at the entrance to the nave, marks the grave of the prelate. The occultist Eliphas Levi was indirectly involved in this tragic event.

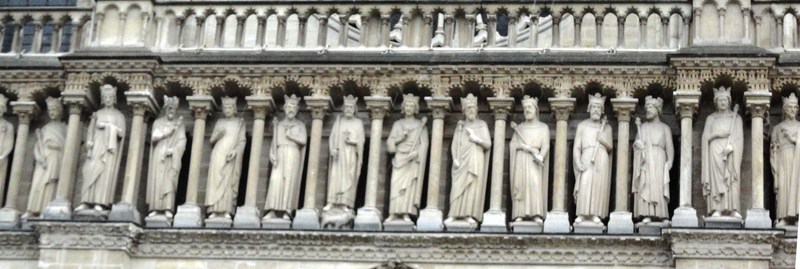

The sculpted The Stoning of Saint Stephen, at the exterior’s tympanum, is the work of French sculptor Gabriel-Jules Thomas. The front facade, which consists of no less than three pediments, features a classical porch. The fourth chapel, on the right from the entrance, contains impressive 16th century stained glass windows.

The church’s impressive interior, which we didn’t see, is characterized by the curved axis of the nave to the transept, the finely carved stone choir screen of Father Biard (1545), his chair (designed by Laurent de La Hyre and sculpted by Claude Lestocart) and its organ case (1631), the oldest in the capital. There’s also a notable wooden pulpit supported by Samson, with a jawbone in hand and a slain lion at his feet.

From 1929 until his death in 1986, renowned organist, composer and improviser Maurice Duruflé held the post of Titular Organist at Saint-Étienne-du-Mont. The interiors and exteriors of Saint-Étienne-du-Mont were featured, in both the beginning and finale, of Max Ophüls celebrated film The Earrings of Madame de… (1953). Popes have also celebrated mass here – Pope Pius VI on January 10, 1805 and Pope John Paul II on August 23, 1997 (during his visit to Paris on the occasion of World Youth Day).

Église Saint Étienne du Mont Church: Place Sainte-Geneviève, Montagne Sainte-Geneviève, 5th arrondissement,75005 Paris, France. Tel: +33 1 43 54 11 79.